QUALITY PROCESS SYSTEMS

Quality Assurance

At ARMOS we believe in long lasting partnerships whereby open communication, operational transparency is vital and the key for success of both parties. We take pride in the fact that we self – perform all of our services and build our team with trusted members, strong work ethics and an acute attention to detail. Our team are trained in best method practices, including the use of products / equipment handling as well as trouble shooting techniques.

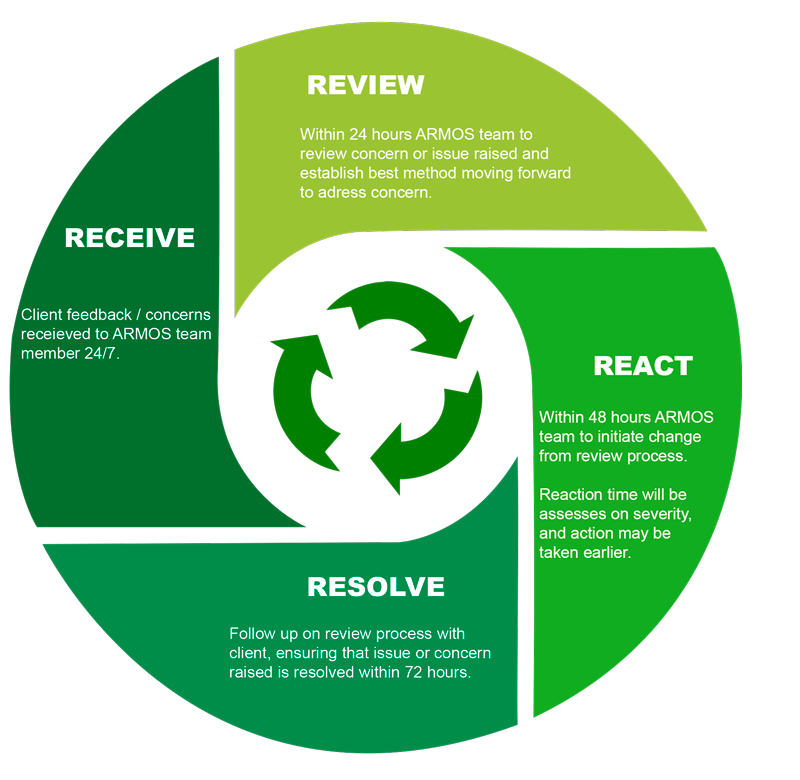

We deploy a quality assurance program to all our clients to ensure that client expectations are met, as we understand that service breakdowns may occur and while we always try to stay on the front foot, we are have also adapted our 4 ‘R’s approach which assists us on delivering our service promise.

Additional Measures are embedded in our processes to maintain our high-quality standards including:

24/7 Hotline:

Quality Auditing:

OUR TRAINING

We believe that our team are our greatest asset, so we invest heavily in all our staff to help them grow and develop. Our training induction begins on the commencement of their employment, covering Safety and Security procedures, first aid, site specific training and task focused training which is then supported by annual refresher training for all team members.

Our training also covers the use of equipment and product that we use. The understanding and knowledge provided in this training, means that we can not only make your space clean and tidy, but truly hygienic and healthy.

Workplace Health & Safety

ARMOS understands the importance or WHS in the workplace, therefore invested in a modular, cloud-based compliance management system to simply and effectively comply with our WHS obligations. This system has 170 full integrate modules, which are specifically designed to automatically address all WHS needs and generates a OH&S management plan.

The online system includes some of the following modules: